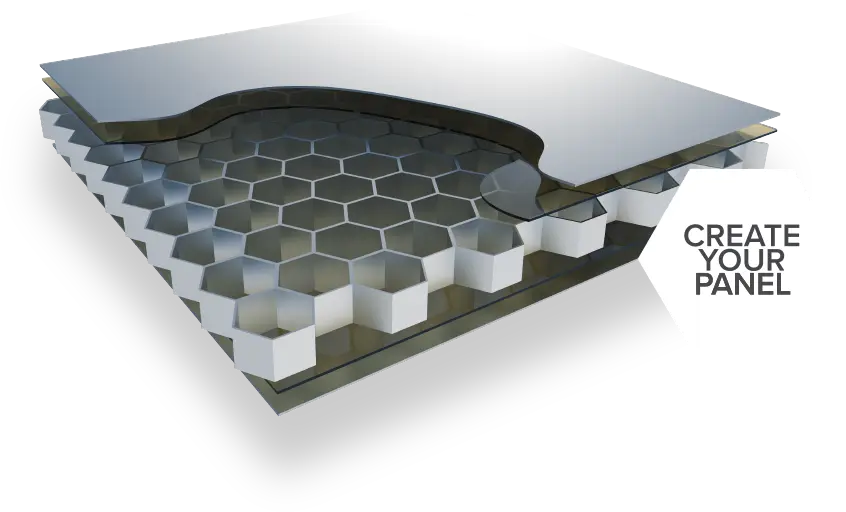

The wide variety of materials that can be used in our TRIPAN lightweight panels allows the construction of very special components. The materials of the lightweight components can therefore be adapted to the most diverse requirements of our customers. The perfect combination of design, functionality and quality speaks for economical solutions with TRIPAN lightweight components.

For really any design and any weather: TRIPAN supplies panel surfaces made of lightweight panel materials such as aluminum, stainless steel, carbon, HPL laminates, laminates, plaster and textile surfaces or perforated and grid sheets in the desired thickness of our customers – from 0.5 mm to 10 mm. The thickness of our top layers can vary depending on the area of application. The top layers of our lightweight components can also be produced with special metals such as titanium, bronze or copper at the customer’s request. The different materials can be fabricated, painted or anodized. Fasteners, lighting and much more can also be integrated into the top layers at the customer’s request. The top layers of TRIPAN honeycomb panels are precisely matched to the requirements – in the architectural field, attention is paid primarily to appearance and a high load-bearing capacity, while in mechanical engineering, weight, stability and the inclusion of holding and stability points are often of great importance. The honeycomb panels can be produced up to a size of 15×3.5m, have a very low weight per unit area (from 3kg per square meter) as well as excellent insulating properties and are also TÜV-certified.

Solid aluminum sheets are lightweight, durable, and corrosion-resistant, featuring a smooth, metallic surface that imparts a modern, industrial aesthetic. Commonly used in construction, automotive, and aerospace industries, they offer strength and lightness. These surfaces can receive appropriate coatings during production to enhance their properties.

Perforated aluminum sheets are chosen for specific visual effects, featuring a patterned surface that varies with hole design. Depending on the degree of perforation, these surfaces, combined with the appropriate structure, can significantly improve room acoustics. They are predominantly used in interior design, though they offer less strength compared to solid sheets.

Aluminum tread plates are slip-resistant and particularly robust, with a distinctive textured surface providing excellent grip, making them ideal for flooring applications. They exude a sturdy, industrial appearance and can be coated upon request to protect against corrosion.

Aluminum mesh is lightweight, flexible, and features a high open area percentage, making it suitable for applications requiring ventilation or filtration. Its open structure allows for airflow while maintaining structural integrity. By offering such a wide range of facing materials and finishes, TRIPAN ensures that each lightweight panel is precisely tailored to meet the specific demands of its intended application, providing both aesthetic appeal and functional excellence.

Solid stainless steel is extremely durable, corrosion-resistant, and long-lasting, though heavier and more expensive than aluminum. Its smooth, shiny surface exudes a modern, high-end look. Stainless steel is commonly used in architecture, kitchens, and medical applications where high hygiene and stability standards are required. A drawback is its heavier processing effort.

Stainless steel mesh offers high corrosion resistance and extreme robustness with an industrial, functional aesthetic. Drawbacks include higher cost, heavier processing effort, and weight compared to aluminum mesh.

Expanded metal is durable, lightweight, and provides excellent stability with minimal material usage. Its honeycomb-like, open structure gives it a modern and functional look. However, it offers limited protection against weather conditions.

Galvanized steel grid is extremely robust and provides excellent corrosion protection. It has a functional, technical appearance. A drawback is its higher weight and less appealing aesthetics compared to finer materials like aluminum or stainless steel.

Carbon fiber is extremely lightweight yet very strong, though it comes with higher costs. It has a distinctive, glossy, woven appearance and is used in high-tech applications such as motorsports, aerospace, and sports equipment. Drawbacks include brittleness upon strong impact and higher costs compared to metals.

Glass fiber polyester is lightweight, robust, and resistant to corrosion and chemicals. Its surface is smooth and can be customized in various colors. It is commonly used in the shipbuilding industry. Drawbacks include susceptibility to UV damage and lower strength compared to carbon fiber.

HPL is durable, scratch-resistant, and available in various colors and patterns. It has a smooth, matte, or glossy finish and is often used in furniture, wall cladding, and countertops. Drawbacks include limited moisture resistance and lower impact resistance compared to metals.

Plexiglass is lightweight, transparent, and more shatter-resistant than glass, though more prone to scratches. It features a smooth, clear, or opaque surface and is commonly used in displays, protective glazing, and furniture. A drawback is its lower scratch resistance compared to glass, despite being lighter and more shatterproof.

Wood veneer is lightweight, natural, and offers a warm, aesthetically pleasing appearance. It is frequently used in furniture and interior design but has lower durability and moisture resistance compared to synthetic materials. Drawbacks include susceptibility to scratches and moisture.

A rubber covering provides slip resistance, shock absorption, and good chemical resistance. It has a functional appearance and is often used in industrial applications, sports flooring, or workshops. Drawbacks include susceptibility to UV damage and limited aesthetics compared to other materials.

Linen offers a natural, textile aesthetic and is lightweight and environmentally friendly. It is often used in interior design and sustainable construction projects. Drawbacks include susceptibility to moisture and dirt, as well as lower strength compared to synthetic materials.

Linen offers a natural, textile aesthetic and is lightweight and environmentally friendly. It is often used in interior design and sustainable construction projects. Drawbacks include susceptibility to moisture and dirt, as well as lower strength compared to synthetic materials.

Linen offers a natural, textile aesthetic and is lightweight and environmentally friendly. It is often used in interior design and sustainable construction projects. Drawbacks include susceptibility to moisture and dirt, as well as lower strength compared to synthetic materials.

Hemp is a sustainable, lightweight, and durable material with a natural, rustic appearance. It is commonly used in interior design and ecological construction projects. Drawbacks include limited durability and moisture resistance compared to synthetic alternatives.

Grass mix is made of natural fibers and offers an eco-friendly, organic look. It is often used in sustainable construction projects or interior design. Drawbacks include lower resistance to moisture and mechanical stress compared to industrial materials.