TRIPAN’s core materials can be made from a wide variety of materials and precisely machined. This means that a functional interior can be integrated directly into the panels – from electrical systems to heat and sound insulation. Every material and every variant of our different core materials offers countless possibilities.

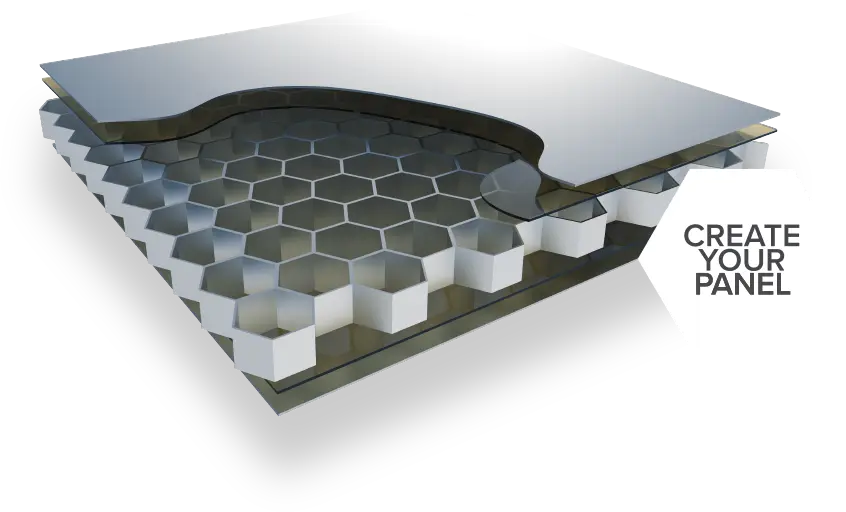

Our TRIPAN composite components utilize a broad spectrum of core materials for lightweight construction. This includes materials such as aluminum, stainless steel, wood-based products, plastics, foams, and more. The choice of core layers significantly influences the properties of the lightweight components. An aluminum honeycomb core provides panels with high compressive and bending strength, while foam cores excel in thermal insulation. The versatility of TRIPAN composites is evident not only in the selection of core layers but also in the targeted placement of inlays. For core materials subjected to high point loads, anchor reinforcements enhance stability. Inserts or shaped tubes are added as needed, enabling precise adaptation to specific requirements, as emphasized by our motto, “Create your panel.”

To provide our customers with the best core materials for lightweight construction, we continuously revise and expand our product portfolio. The increased use of renewable raw materials is reflected across diverse applications. As a result, resource-saving materials are increasingly used in lightweight construction.

The hexagonal aluminum honeycomb offers an excellent strength-to-weight ratio, providing high compressive and bending strength with low weight. A downside is its limited thermal insulation capability. It is commonly used in aircraft, vehicle, machinery, and cabin construction as well as in architecture. This material is crucial for thermally activated ceilings, where it conducts and radiates heat efficiently.

Made from aramid fiber paper, Nomex honeycombs deliver exceptional strength with minimal weight. They feature good fire resistance and are frequently used in aerospace applications. However, they are more expensive and offer less stiffness than aluminum honeycombs.

A cost-effective, lightweight solution with good load-bearing capacity, cardboard honeycombs lack durability and moisture resistance. They are often used in packaging, temporary partitions, and furniture where sustainability and recyclability are priorities.

Corrugated cardboard honeycombs provide slightly higher stability than standard cardboard honeycombs but are still susceptible to moisture and mechanical damage. They are used in lightweight, temporary constructions and eco-friendly packaging, focusing on cost and sustainability.

Lightweight, moisture-resistant, and chemically durable, PP honeycombs offer less stiffness than aluminum. They are commonly used in automotive, packaging, and furniture industries where low weight and longevity are essential.

Polycarbonate honeycombs are impact-resistant and transparent, but heavier and more expensive than other plastics. They are used in areas requiring optical clarity and robustness, such as translucent structures and protective covers.

Rock wool provides excellent thermal and sound insulation as well as fire resistance. However, it is heavier and less stable compared to other core materials. It is widely used in construction, especially where fire safety is critical.

PUR recycling material is eco-friendly, lightweight, and offers good insulation properties. However, it is less dimensionally stable and less fire-resistant than other materials.

Polystyrene foam is lightweight, provides good thermal insulation, and is cost-effective. However, it is not highly fire-resistant and has limited mechanical strength. It is used in vehicle construction, buildings, and more.

PUR foam cores offer excellent thermal insulation and low weight but are sensitive to UV radiation and moisture. They are commonly used in vehicle construction, buildings, and other industries.

Made from recycled PET (e.g., plastic bottles), this core offers an environmentally friendly alternative. It is lightweight, stable, and moisture-resistant but more expensive than other foam cores. It is often used in mechanical engineering and vehicle construction.

PVC foam cores provide a good balance of lightweight, high strength, and moisture resistance. Their limited environmental friendliness is a drawback. Applications include shipbuilding, sports equipment, and vehicles.

This foam offers excellent fire resistance and strength but is heavier and costlier than other foam types. It is commonly used in fire protection, sandwich panels, and aerospace.

Aluminum foam is extremely lightweight, provides good strength, and is fire-resistant, but it is expensive and less commonly used. Applications include high-end automotive and aerospace industries.

Balsa wood is extremely lightweight and highly compressive but prone to moisture and pest damage. It is frequently used in shipbuilding and aerospace as a core material for composites.

Cork is lightweight, elastic, and offers excellent insulation and soundproofing properties. It is relatively expensive and sensitive to mechanical stress, making it ideal for sustainable construction projects.

Laminated wood offers high stability and load-bearing capacity but is heavier and more moisture-sensitive than synthetic materials. It is primarily used in projects where sustainability is a key concern.