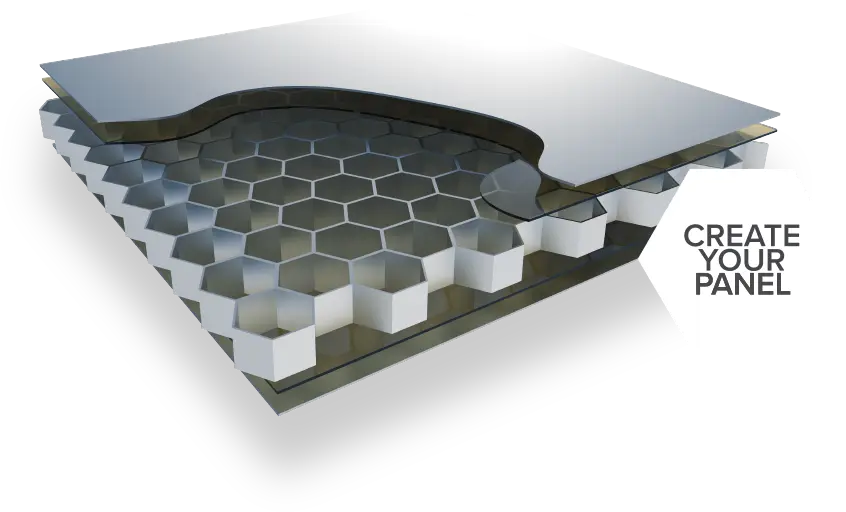

TRIPAN offers high-quality coating solutions that significantly enhance the functionality and durability of lightweight panels. Whether for protection against external influences, optimization of technical properties, or an appealing design, the coatings are tailored to the specific requirements of each project.

By utilizing state-of-the-art technologies, TRIPAN ensures precise processing and the highest quality standards to efficiently meet even the most demanding requirements.

To achieve a perfect finish, various coatings can be applied to our surface layers. Depending on the type of material, we offer a wide range of coating options, from anodizing and powder coatings to various lacquer finishes. These coatings are available in a variety of colors, allowing for almost limitless design possibilities. Whether matte, glossy, or textured – we customize the surface to suit your design preferences.

Coatings are not only essential for aesthetics but also for protecting the components. Particularly regarding corrosion resistance, coatings provide a reliable barrier against environmental influences and significantly extend the lifespan of the materials. Additionally, specialized coatings can add properties such as increased scratch resistance or chemical resistance, making them ideal for demanding applications. Our coating solutions thus provide both functional and aesthetic benefits.

Anodizing is an electrochemical treatment for aluminum that creates a hard, durable surface. It provides high corrosion resistance and is abrasion-resistant. The natural metallic appearance is preserved but can also be color-adjusted. Disadvantage: Color options are limited, and anodizing is only suitable for aluminum.

Powder coating is available in many colors and textures. It offers high protection against corrosion and scratches. A disadvantage is the difficulty in repairing small damages. Powder coating creates a durable, uniform surface that can appear matte or glossy.

Paint provides a smooth, glossy, or matte surface in a wide range of colors. It is highly versatile but less resistant to scratches and wear compared to powder coating. Its advantages include flexibility and the ability to easily touch up or renew surfaces.

Digital printing enables detailed and customized designs on nearly all surfaces. It offers maximum flexibility for designs, ranging from images to complex patterns. A disadvantage is its lower durability compared to other coatings, especially under mechanical stress. Visually, it impresses with vibrant colors and variety.

Plaster creates a textured, matte surface suitable for both interior and exterior applications. It provides protection against weather influences and is available in various textures. A disadvantage is its lower resistance to mechanical damage. Visually, it offers a robust, artisanal look.

This represents the untreated surface of aluminum sheets. In technical applications, this surface is often sufficient. However, it is more prone to corrosion.

This coating provides a highly reflective, mirror-like finish for applications requiring maximum brightness and clarity.

A satin reflector mirror offers a softer, less reflective surface, ideal for applications requiring a balance between reflectivity and subtlety.

Diffuse matte reflector coatings offer minimal reflectivity, creating a subdued, matte appearance suitable for functional or aesthetic purposes.